Product Overview

Performance Grade (PG) bitumen is bitumen categorized according to how well it performs under various temperature conditions. The LTPP has provided a specific algorithm for determining pavement temperature using the air temperature as a reference point. This information is used to determine the highest and lowest temperatures the pavement will experience, and to choose the appropriate bitumen for those conditions.

Penetration grading and viscosity grading have some limitations in fully characterizing asphalt binder for HMA pavement. Hence, in the super pave research project, new binder tests and specifications were created to thoroughly characterize asphalt binders for HMA pavements. These tests and specifications are crafted with the specific purpose of focusing on HMA pavement performance parameters like rutting, fatigue cracking, and thermal cracking.

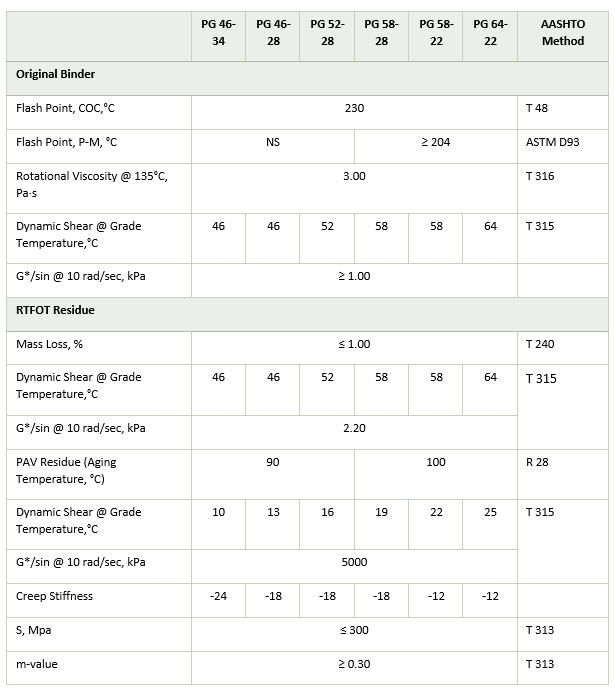

Super pave performance grading (PG) is founded on the concept that the characteristics of an HMA asphalt binder should be linked to the circumstances it is subjected to during usage. For asphalt binders, this includes anticipated weather conditions and factors related to aging. Thus, the PG system requires a standard set of tests, like the older penetration and viscosity grading systems, but mandates that each asphalt binder must meet these test requirements at temperatures based on the local climate. This idea is not novel – choosing penetration or viscosity graded asphalt binders is based on the same principle – however, the connections between asphalt binder characteristics and usage conditions are more thorough and accurate with the super pave PG system. The super pave mix design method contains guidance on choosing a PG asphalt binder for specific conditions. The table presented illustrates how the super pave PG system deals with penetration in a particular manner.

PERFORMANCE GRADE BITUMEN (PG BITUMEN) PRODUCTION PROCESS

In the field of pavement engineering and road construction, Performance Grade (PG) Bitumen, also called Asphalt Binder, is a crucial material. This higher quality bitumen, in comparison to standard penetration grade bitumen, has improved performance qualities, making it the top pick for strong and long-lasting road surfaces.

The PG Bitumen production process consists of four key stages: distillation, air blowing, polymer modification, and thorough testing.

The feline leaped onto the table. Distillation is the process of separating components in a liquid mixture by heating and cooling to create a purified substance.

At first, crude oil undergoes atmospheric distillation at approximately 350°C. The lighter hydrocarbons evaporate, while the heavier hydrocarbons, also called bitumen feedstock or vacuum bottoms, remain.

The company will be implementing new security measures to protect its customers’ data. Blowing air through a tube.

Next, the bitumen feedstock is transferred to a bitumen blowing unit, where hot air is added. Oxygen interacts with the feedstock, causing alterations in the physical characteristics of the bitumen, commonly referred to as “oxidation”. Oxidized bitumen is the final outcome.

The third item is called the “Particle Soup,” made with a blend of various particles that give it a unique and flavorful taste. Modifying polymers:

Specific polymers are added to bitumen to improve its performance characteristics. Frequently utilized polymers consist of Styrene-Butadiene-Styrene (SBS) and Atactic Polypropylene (APP). Adding these polymers enhances the elasticity, thermal characteristics, and deformation resistance of the bitumen.

The conference was informative and engaging. Evaluation:

The last stage involves thorough testing to verify that the PG Bitumen meets the specified criteria. Experiments are carried out to analyze the rheological characteristics, such as how bitumen reacts to varying temperatures and loading durations. The performance grade of the bitumen is determined by these characteristics.

The creation of PG Bitumen is a complex process that necessitates accuracy, cutting-edge technology, and knowledge of crude oil and polymers’ characteristics. The result is a top-notch bitumen that plays a key role in building excellent road infrastructure, leading to safer and more comfortable travels.

PERFORMANCE GRADE BITUMEN (PG BITUMEN) PROPERTIES

Performance Grade Bitumen, also known as PG Bitumen, demonstrates multiple important characteristics that render it appropriate for a range of uses in the construction sector. Below are several key characteristics of PG Bitumen:

1. Viscosity: PG Bitumen has a specific viscosity range that determines its flow characteristics at different temperatures. This property ensures proper coating and adhesion to aggregates during the mixing and compaction process.

2. Penetration: Penetration refers to the depth (in tenths of a millimeter) that a standard needle penetrates into the bitumen under specified conditions of time, temperature, and loading. PG Bitumen has a controlled penetration value, which influences its consistency and ability to resist deformation under traffic loads.

3. Softening Point: The softening point of PG Bitumen is the temperature at which it reaches a specific level of softening. This property is important because it indicates the bitumen’s resistance to deformation under high temperatures and helps determine its appropriate use in different climatic conditions.

4. Ductility: Ductility measures the bitumen’s ability to stretch without breaking. PG Bitumen exhibits a certain level of ductility, which is essential for preventing cracking and ensuring the longevity of the pavement.

5. Elastic Recovery: Elastic recovery refers to the ability of bitumen to return to its original shape after being stretched. This property helps the pavement withstand repetitive traffic loads without experiencing permanent deformation.

6. Rheological Properties: PG Bitumen undergoes rheological testing to evaluate its performance characteristics under different temperature and loading conditions. These properties, such as complex modulus and phase angle, help determine the bitumen’s ability to resist rutting, fatigue, and thermal cracking.

7. Ageing Resistance: PG Bitumen is designed to resist the effects of aging caused by exposure to air, water, and sunlight. Its formulation includes additives that enhance its long-term durability and prevent premature deterioration.

Having a thorough understanding of these characteristics is essential when choosing the right Performance Grade Bitumen for certain uses, ultimately guaranteeing the durability and effectiveness of the pavement. Consulting the appropriate specifications and standards is crucial in identifying necessary properties according to project needs and environmental factors.