The basics of lubricants: base oils

Technical Expertise

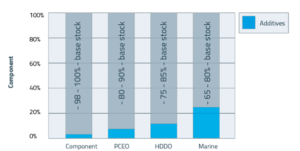

When discussing the fundamentals of lubricants, base oils (or base stocks) are the logical point of departure. Making up 70-95% of a lubricant’s makeup, these oils are regarded as its primary ingredient.

Base oils are not naturally occurring and instead go through a refining process from crude oil. Typically, around 2% of global crude oil production is dedicated to manufacturing lubricants. However, there are several steps to follow in order to transition from crude oil to base oils.

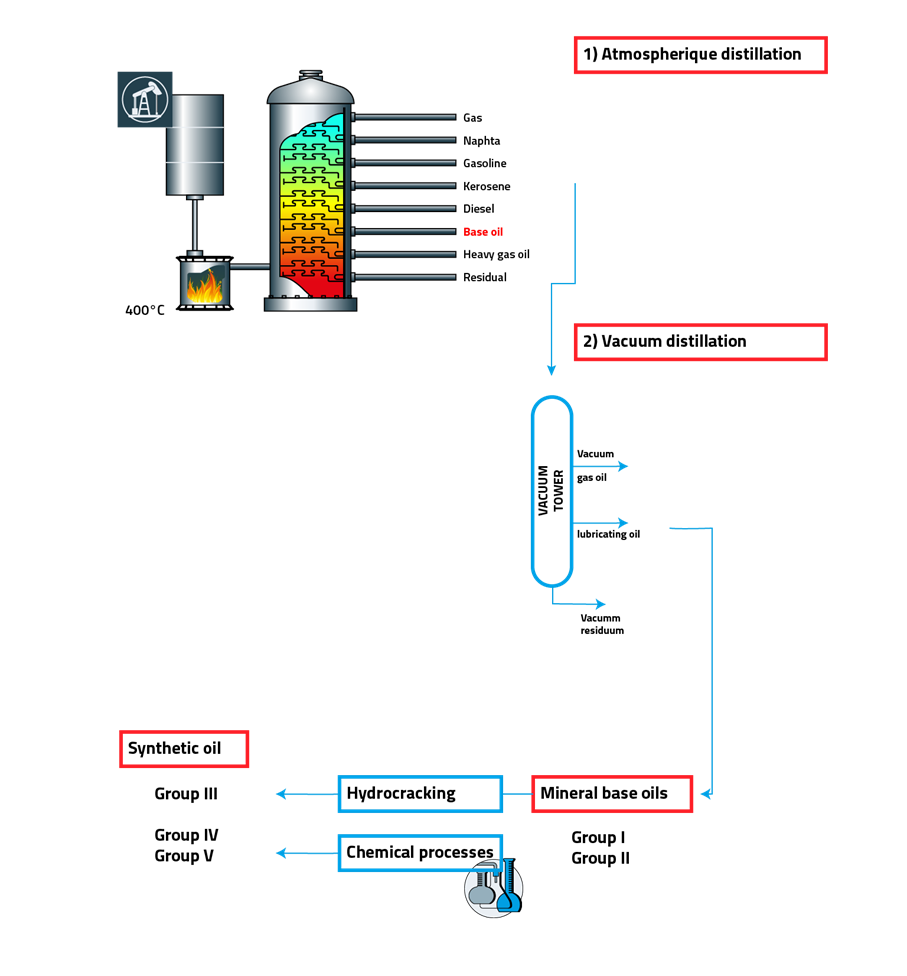

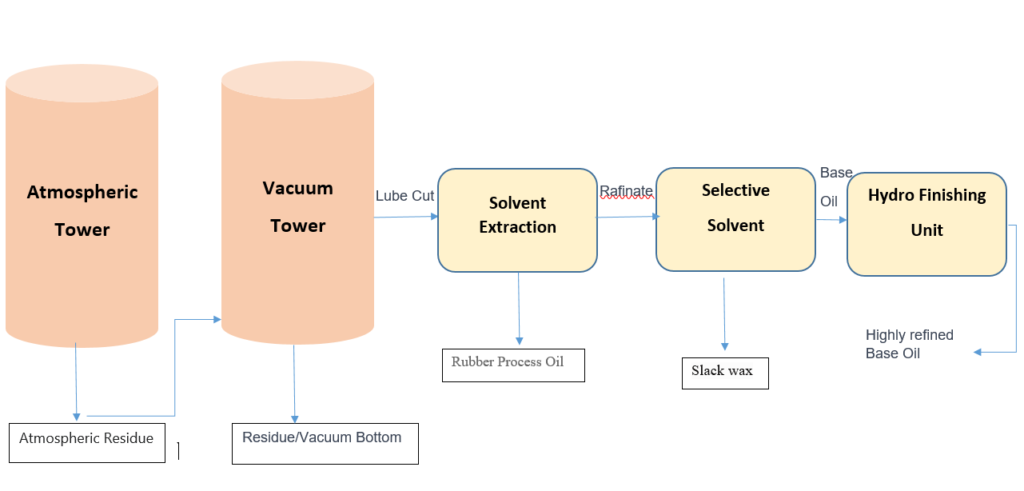

• Initially, crude oil undergoes two distillation procedures: Atmospheric distillation and vacuum distillation. Following the second distillation process, base oils undergo a comprehensive examination to confirm they exhibit correct test outcomes for vital attributes. Some examples of important features of base oils include viscosity, volatility, and oxidation stability. In the end, we have base oils prepared for blending with additives. This topic will be addressed in the upcoming chapter.

Distillation involves separating substances, such as liquids and vapors, through the use of high temperatures. During the process of atmospheric distillation, crude oil is warmed to approximately 400°C, which speeds up the movement of the oil molecules into a separation of liquids and vapors within the distillation tower. Because liquid is denser, it tends to remain towards the bottom of the tower compared to the vapors, which rise towards the top.

Some fractions can be obtained from heated crude oil and are immediately usable (such as gases), while only base oils undergo a second distillation. The second distillation is conducted in a vacuum environment, allowing for the production of distillates with elevated boiling points at reduced temperatures and resulting in base oils as the final product.

Base oils can be divided into two main categories based on the treatments they undergo.

• Mineral base oils: Base oils group I and II are mineral base oils that have been extracted from crude oil through the refining process.

• Synthetic base oils: Synthetic base oils, group III, are mineral base oils that have been refined through hydrocracking, while group IV and V oils are solely produced through synthetic or chemical processes.

*Hydrocracking mineral base oils means cracking heavy, high-sulfur molecules of the oils into better quality, low-sulfur molecules under high temperature and pressure.

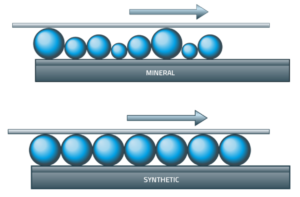

Synthetic base oils are created through specific chemical procedures to enhance their performance, due to their uniform molecular structure and high purity levels. Due to the molecules’ uniform size and shape and their strong adhesion, the metal surfaces will experience reduced friction and achieve a much-improved performance overall.

Different types of base oils have varying impacts on the performance of the engine. Utilizing additives boosts these results and introduces extra advantageous qualities to the lubricant. The quantity of additives differs from one segment to another

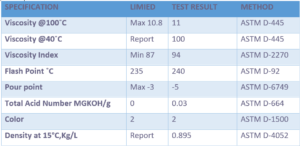

Before incorporating additives, a detailed examination of all fundamental oil traits is carried out. Some key traits include:

Petroleum Base Oils

Group I

Group I base oils are the most basic type of base oil in terms of refinement. Group I base oils are mainly defined by their low saturates content of less than 90% and high sulfur content of over 0.03%. If any of these requirements are met, the base oil will be labeled as Group I. The sole method employed is solvent refining, resulting in lower prices for Group I base oil compared to higher refined options. These are typically utilized for less challenging tasks and may be perfect for situations with high lubricant usage.

Group II

Group II base oils undergo further refinement compared to Group I. Besides solvent refining, they also undergo hydrocracking to purify the oil. Contrary to Group I base oils, these base oils have to have more than 90% saturates and less than 0.03%. These lubricants have improved autoxidation properties compared to Group I base oils due to their higher percentage of saturates.

Failure to fulfill either of these criteria will lead to a Group I categorization. These items also fall within a viscosity index range of 80-120. These oils show strong performance in terms of volatility, resistance to oxidation, ability to prevent wear, and flash point. Their performance is only decent in cold temperature settings. Due to current treatment costs, Group II lubricants are now widely preferred over Group I oils by many users. Informally, there exists a Group II+ which consists of premium Group II base oils. Base oils need to have a viscosity index between 110 and 120 in order to be classified as Group II+.

Group III

Group II base oils are required to satisfy the same criteria (saturates and sulfur) as Group II oils, in addition to having a viscosity index that exceeds 120. The base oils undergo intense hydrocracking, hydro isomerization, and hydro treating to produce top-quality petroleum base oil. These items provide excellent stability and consistent molecular structure, making them well-suited for certain semi-synthetic lubricants.

Some individuals view Group III base oils as synthetic. The API considers them mineral oil because they come from crude oil. They imitate qualities of synthetic oils, such as having high viscosity indices. Mobil sued Castrol for promoting their syntax lubricant as synthetic when it actually contained Group III base oils. In a ruling from 1999, the product was approved for sale as a synthetic.

A lot of individuals refuse the choice and exclusively view Group IV and Group V base stocks as “synthetic.” Certain Group III lubricants can exceed the performance of Group IV lubricants when they include high-quality anti-wear, anti-oxidant, and additional additives. Like Group II, Group III base oils also have an informal Group III+ category, which includes Group III oils with a “Very High Viscosity Index (VHVI).” The VHVI minimum ranges from 130 to 140.

An overall shift is occurring towards higher quality synthetic base oils, mostly influenced by environmental standards and requirements. Advances in technology over the last ten years have led to engine models that necessitate advanced oil blends. Previously, mineral base oils were suitable for all engine types, but the latest engine models no longer allow for this oil type.

Types of base oil that are exported by Abm-petro100 C` kinematic viscosity

Product Overview 180N

base oil is utilized in a range of industries because of its favorable physical and chemical characteristics. A few of its primary purposes are:

• Industrial lubricants: utilized as the foundation for creating industrial lubricants for use in industrial machinery and equipment.

• Motor oils are a key ingredient in the motor oils utilized in internal combustion engines.

• Hydraulic Oils: Used as a foundation for producing hydraulic oils for hydraulic systems.

• Heat transfer oils are utilized in heat transfer systems because of their exceptional thermal stability.

Get in touch with our team for the technical information of this product if you require it.

Product Overview SN 150

The item is derived from the vacuum fraction of crude oil, carefully refined to remove solvents, dewaxed, and hydro-refined. These processes allow for achieving the preferred characteristics in the end product, including absence of low-index substances, improved color, and favorable low-temperature and thermo-oxidation properties. Base oil SN 150 is designed for use in the manufacture of lubricants.

Base Oil SN150 Applications

Base oils are utilized in making lubricating oils, oil products, greases, and plasticizers.

• Because of the distinctive qualities of this oil, benefits such as:

• Stability of character during operation

• Bright color

• Optimal oxidation and thermal stability

• Low volatility

• Excellent viscosity stability

• Appropriate viscosity index

• High flash point

• Minimal sulfur content

Product Overview SN 350

SN-350 base oil is categorized as a Group I base oil and is referred to as a light-grade base oil. It is frequently utilized in the manufacturing of lubricants and viscosity enhancers.

Solvent extraction and hydrogenation processes are used to eliminate impurities, resulting in a refined and purified product. This oil is classified as a medium-grade base oil in terms of quality and characteristics.

Base Oil SN350 Applications

SN350 base oil is utilized in numerous sectors because of its distinctive technical qualities. Some of the uses of this oil include the following:

• Base oil SN350 is employed as a raw material in the manufacturing of industrial lubricants for heavy machinery and equipment.

• Hydraulic oil is utilized in hydraulic systems because of its ability to remain stable at various temperatures.

• Motor oils are utilized alongside additives as motor oil to enhance engine performance and prolong its longevity.

Get in touch with our team for the technical information of this product if you require it.

Product Overview SN 600

SN 600 base oil is an extensively purified petroleum oil utilized as a lubricant in different industrial uses. We will explore Base oil SN 600 in detail on this page, including its product description, specifications, chemical formula, properties, and applications.

Base oil SN600, also referred to as bright stock, is a meticulously purified mineral oil derived from a method involving solvent extraction and hydro-treating. This is a Group I base oil variety made from crude oil and is known as the least refined among all base oils. SN-600 base oil is commonly utilized in mixing lubricants and greases, along with creating additives for them.

Base Oil SN600 Applications

SN 600 base oil is utilized in various industrial uses, such as:

Base oil SN-600 is frequently utilized as a blending ingredient in the manufacturing of engine oils, gear oils, and transmission fluids in the automotive lubricants industry.

Industrial lubricants are also utilized in heavy machinery like hydraulic systems, compressors, and turbines during manufacture.

Base oil SN 600 is suitable for use as the primary fluid in metalworking fluids, which serve to cool and lubricate cutting tools while they are in use.

Additive manufacturing is utilized for creating additive packages for lubricants and greases as well.

Base oil SN600 is utilized as a plasticizer and lubricant in the manufacturing of rubber and plastic goods.

Get in touch with our team for the technical information of this product if you require it.